Areas of Specialisation and System Understanding

System Understanding

System Understanding

It is of utmost importance to understand clients need, project requirment before installing any system. Even the simplest of activities like installing a waste and soil down take pipe involves understanding and designing.... sizing, venting, final disposals are key factors which need to be looked into before installation.

A well designed system backed by technical support (backend and frontend) would provide a well balanced maintenance free installation... implementation of the same is happening at Dsa day-in and day-out since 1984.

Our Areas of Competence Are:

- Fire Detection

-

"Prevention is better than cure" - A well-designed Fire-Detection System can detect and help prevent a major disaster "FIRE". Our systems are custom designed to suit specific needs of the project. Intelligent fire alarm system integrated with the latest in computer technology is the only best available FIRE DETECTION SYSTEM - We at Dsa provide it, a well designed but slow response system is equally bad and meaningless as a badly designed system.

"Prevention is better than cure" - A well-designed Fire-Detection System can detect and help prevent a major disaster "FIRE". Our systems are custom designed to suit specific needs of the project. Intelligent fire alarm system integrated with the latest in computer technology is the only best available FIRE DETECTION SYSTEM - We at Dsa provide it, a well designed but slow response system is equally bad and meaningless as a badly designed system.

With regular in-house QMS programs and regular upgradation of systems, we are capable of designing and erecting a well-balanced fire detection system.

Fire detection system comprises of a well-placed network of detectors (smoke, Ionisation, PIR) wired to the PLC based annunciation panel with an audio-visual alarm.

The entire system can be monitored and controlled through BMS (Building Management System) in other words through a Central Computer.

- Fire-Fighting System

-

Here, we design and erect a well-balanced system to enable our customers to successfully fight any category of fire. Here, we design and erect a well-balanced system to enable our customers to successfully fight any category of fire.

Fire-Fighting System comprises of:

- Wet or Dry Hydrant System: Wet hydrant system is an automatic system under constant pressure, operation of any hydrant valve would result in the automatic starting of the pumps. Dry hydrant system is a manual system

- Sprinkler System: This is a system hydraulically designed keeping in the mind the kind of Sprinklers to be used. The system becomes operative as soon as the sprinkler bulb bursts in case of fire.

- Emulsifier System: This system becomes operative through the Fire-Detection system.

- Gas Flooding System: This system is ideally used for fighting electrical fires (HT/LT), fuel fires and fires in computer rooms.

This system is integrated with the fire detection system and activates automatically when needed.

All the above are monitored through the BMS which also monitors close/open condition of control valves, operation of solenoid valves and deactivation of pumping system in case of false operation.

Our system are designed in accordance to prevailing ISI, NFPA and NBC codes.

- Public Health Engineering (PHE)

-

Plumbing and Sanitary works are the HEART of any property whether commercial or institutional, A bad system is always irrepairable and causes immense frustration to the Owners and damage to the property. Some of the commonly faced problems are choking, leakage due to backpressure, bad co-ordination of high side installation etc. Plumbing and Sanitary works are the HEART of any property whether commercial or institutional, A bad system is always irrepairable and causes immense frustration to the Owners and damage to the property. Some of the commonly faced problems are choking, leakage due to backpressure, bad co-ordination of high side installation etc.

We at DSA have achieved high efficiency levels due to constant upgradation and education in the field of PHE.

Our CMD - Mr. Devendra Singh has been certified as an honorary Member of The Royal Society of Health (London) for his outstanding work in the field of PHE.

Our past association with Thermax and Ion Exchange as their Business partners has given us vast exposure in designing well balanced systems (Water and Waste management) and erecting equipments following high standards of engineering practice.

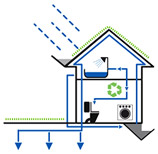

- Water Management & Distribution

-

We were the first one's in India to design and install a pressurised system (Hydropneumatic System) - in the mid 60's - and since then have designed and installed many systems.

We were the first one's in India to design and install a pressurised system (Hydropneumatic System) - in the mid 60's - and since then have designed and installed many systems.

With regular technical upgradation we have succeeded in designing & erecting state of the art systems compatible to the central BMS systems with logic display consoles. The entire operation is controlled and monitored through BMS.

- Waste Management

-

A well designed and well sized disposal system ensures smooth flow of waste, thereby eliminating back flows, constant flooding etc. at DSA we believe in getting rid of your dirt effortlessly.

A well designed and well sized disposal system ensures smooth flow of waste, thereby eliminating back flows, constant flooding etc. at DSA we believe in getting rid of your dirt effortlessly.

Venting of soil and waste disposal system is one of the most important concerns. We at DSA have introduced an internationally time tested solution in India using Air Admittance Valves which result in eradication of Vent Stacks, a cost effective solution to conventional venting.

- Water & Waste Treatment Plant

-

A lot of equipments are available for water and waste treatment but putting all the right equipment at the right place and detailed designing of the same is important - this is where DSA comes into operation:

- Water Filteration Plants.

- Water Softening Plants.

- Revere osmosis plants.

- De-ionisation Plants.

- Sewage Treatment Plants.

- Industrial Waste Treatment Plants.

It is also essential to determine the material of construction of pipes used after treatment to avoid corrosion of pipes installed.

Our CMD Mr. Devendra Singh (MIWWA), AAE (INDIA), MIAWPC, MRSH (London) - member of Bureau of Indian Standards (ISI) Sectional Committee CED-24 is personally involved with the Design, Implementation and Quality Management of each and every projects.

The company boasts of its Technical Strength in the above areas, which has been achieved due to the joints efforts of all our Technical, Administration and Site Team.

The best of our capabilities can be exploited by appointing us as your Turnkey Contractors - to design and erect the above systems.

- Utility Piping

-

The term Utility Piping means "Piping for Specialized Applications". Here the methodology of doing the piping is not important, what is important is the type of material used, understanding the grade & type of piping required for specialised equipments in different applications.

The term Utility Piping means "Piping for Specialized Applications". Here the methodology of doing the piping is not important, what is important is the type of material used, understanding the grade & type of piping required for specialised equipments in different applications.

We have vast experience in executing specialised piping works such as Pharma applications, compressed air applications, steam distribution etc.

Some of our valued clients have been Machino-Plastics, Meher Pharma, Marriott, ITC Hotels, Vitro Pharma... etc.

- Mechanical Installation (Piping & Plants)

-

Catering to different client requirements of high side installations lead to opening of a separate division at DSA to look into the designing, procurement and installation of high-end equipments. Catering to different client requirements of high side installations lead to opening of a separate division at DSA to look into the designing, procurement and installation of high-end equipments.

Here we have had the privilege of executing various projects involving Steam generation and distribution, Hot water generation and distribution, HSD storage installation and distribution, Scrubber and ETP/STP design and installations etc.

Having experience in maintenance also, designing of plant room installations are done keeping in mind the requirements of their maintenance team vis-à-vis space distribution, piping details, adequate space requirements for movement etc.

- Civil Engineering

-

Here we are catering to a niche market, our clients have been Sterling Hotels, Ramada Hotels (now known as Renaissance), Coca-Cola, Juhu Hotels, Meher Pharma .. etc. Here we are catering to a niche market, our clients have been Sterling Hotels, Ramada Hotels (now known as Renaissance), Coca-Cola, Juhu Hotels, Meher Pharma .. etc.

Besides the above commercial projects we have also executed civil works for residential purposes, mainly farm houses and bungalows.

- Vaccum Drainage System

-

Conventional drainage systems (gravitational) are not only expensive but require constant maintenance. They are the breeding ground for rodents, cockroaches etc. Installing a conventional drainage system is expensive in large housing colonies, Commercial establishments where external land may not be available for laying underground piping systems and where the soil conditions may not be conducive to laying the underground piping system (hard/rocky strata), or where the sewerage has to be transported against gravity, or where water tables are very high. Laying conventional drainage system in the above mentioned areas could cost more money by way of indirect expenses and may also require regular maintenance of chocked lines, maintenance of manholes, collections pits, and installation of submersible pumps etc. Conventional drainage systems (gravitational) are not only expensive but require constant maintenance. They are the breeding ground for rodents, cockroaches etc. Installing a conventional drainage system is expensive in large housing colonies, Commercial establishments where external land may not be available for laying underground piping systems and where the soil conditions may not be conducive to laying the underground piping system (hard/rocky strata), or where the sewerage has to be transported against gravity, or where water tables are very high. Laying conventional drainage system in the above mentioned areas could cost more money by way of indirect expenses and may also require regular maintenance of chocked lines, maintenance of manholes, collections pits, and installation of submersible pumps etc.

Vacuum Drainage system is the most ideal alternate to conventional gravity disposal system. Molecular Drag pumps can develop 29" of vacuum column, thus generating 200 mtr.cube of air, thereby pulling drainage at a velocity of 6 meters per second. The system is capable of pulling practically everything; from sewage to sanitary napkins, bones, vegetable waste, grease even chains, curtains, cloth, thick viscous liquids and much more, every operation leaves the pipe clean and empty, no air , no water hence no growth of bacteria, no chockages.

No manholes are required since no maintenance is necessary, deep excavation is not required since the system works against gravity.

Advantages at a Glance

- Transporting Drainage becomes hassle free and remains cost effective.

- External disposal does not require excavation.

- Drainage is transferred against gravity.

- Sewage travels at high velocities of up to 6 meters per second.

- The most ideal solution for areas having hard strata, high water line areas and large sewage disposal network.

- NO CHOKAGES * NO BAD ODOUR * NO MANHOLES

- MAINTENANCE FREE

- PROVEN TRACK RECORDS WORLD WIDE

Working of such a System

Vacuum systems can be used to collect a variety of fluids, however they are most commonly used to collect sewage from within domestic housing developments.

The three main components of which are as follows :

- Valve Chambers serving two purposes; a) to collect the effluent discharged from the connecting properties, and b) to allow the collected sewage to enter the sewer network via the Iseki interface valve.

- Vacuum Sewers forming the pipe network through which vacuum pressure is transferred to the Iseki interface valves within the collection chambers and along which the effluent is transported to the vacuum station.

- Vacuum Station being the heart of the system and is where the vacuum pressure is generated for the whole sewerage network which allows the effluent to be collected and forwarded to the sewage treatment plant.

THE FUNCTION OF EACH ELEMENT ARE BRIEFLY EXPLAINED HEREIN BELOW.

The Valve Chamber

Sewage arrives via normal gravity pipes at the lower section, or wet sump, of the valve chamber just like a manhole in a conventional gravity system.

As the level of the effluent within the wet sump rises, air is trapped in a pipe called a 'sensor pipe', the pressure of which increases as the effluent level continues to rise.

This increase in air pressure is subsequently transferred via flexible tubing to the top section of the interface valve which is known as the 'controller'.

Eventually this pressure becomes great enough to operate a switch within the controller which then allows vacuum pressure to be transferred to the main body of the valve and cause it to open.

With the valve in the open position, air at atmospheric pressure acting on the surface of the liquid within the wet sump then forces the sewage into the 'suction pipe', past the interface valve and onward into the sewer pipe network.

Once all of the sewage has been removed from the wet sump, the valve remains open for a short period of time to allow air at atmospheric pressure to enter the sewer pipe network.

The valve then closes under the action of a spring to complete one cycle.

|

|

We were the only company in India qualified by GEC Alsthom England to bid and design the Fire-Detection and Fire-Fighting System of Rosa Power Plant in India.

Our CMD Mr. Devendra Singh (MIWWA), AAE (INDIA), MIAWPC, MRSH (London) - member of Bureau of Indian Standards (ISI) Sectional Committee CED-24 is personally involved in the Design, Implementation and Quality Management of each and every project.

The company boasts of its Technical Strength in the above areas, which has been achieved due to the joint efforts of all our Technical, Administrative and Site Teams.

Work pressures do not deter us, infact they encourage us, energise us and ultimately add more experience to our expertise.

Wait and watch... we are your next Turnkey Solution provider to design and erect any/all of the above.

It does not cost to Call us. |

| |

|

|

|

|

|

|

|

|

|

|

|

DSA Engineers (Bombay)

B-43 / B,

Ground Floor (near HDFC Bank),

Kalkaji, New Delhi 110 019, INDIA.

Tel: 91-11-41675560, 26431032, 26475132

|

|

|

|

|

|

|

|